Midwest Dies sets itself apart from the competition by delivering on our promise. To make Accurate, Affordable Steel Rule Cutting Dies that are on time.

Using steel rule cutting dies is a very popular method for cutting out finished parts. Dies are made from hard and sharp steel which is bent and placed into a wooden base to hold shape and specific tolerances.

Most high quality steel rule dies are laser manufactured holding a +/- .010” However, Midwest Dies uses a newer technology that consists of using a two part die board and a precision cutting router. This allows Midwest Dies to hold tolerances of +/- .005”. This also allows two precision tight places to hold the steel rule in place compared to one that you get with a laser die.

Most high quality steel rule dies are laser manufactured holding a +/- .010” However, Midwest Dies uses a newer technology that consists of using a two part die board and a precision cutting router. This allows Midwest Dies to hold tolerances of +/- .005”. This also allows two precision tight places to hold the steel rule in place compared to one that you get with a laser die.Theirs

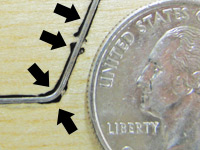

A traditional laser die leaves one side of the board “blown out”. This allows wiggle room for the steel rule to move and doesn’t provide for a precision tight die board.

Ours

Midwest’s steel rule dies are created by two separate boards. By doing this we eliminate the “blown out” effect, providing twice the holding power and stability for the steel rule. As a result, we create some of the most precision dies in the industry!

Our Process

When making a steel rule cutting die, steel rule is cut, bent, and placed into a pre-cut die board. Rubber is then used to help eject parts from the die. Rubber size and density will be selected based on the material that is cut out. Midwest Dies usually uses a standard center bevel rule which is the most common. It provides a long life when used properly in terms of wear. Specific applications will require different rule for certain cuts or tolerances and will be used when appropriate.

Expert help and Instant Quote

Call to talk with one of our experts about your next project: 608-785-0300 or click here for an instant online quote!